- Test Drives

- Application of 5G and AAS digital twin for an automobile parts producer.

Applying 5G plus Asset Administration Shell digital twins to an auto parts production line.

Korea Industry 4.0 Association on behalf of Gyeongnam Techno Park (2023 12/20)

OVERVIEW

This IIC Test Drive employs a 5G private communication network to demonstrate the efficiency and reliability of 5G for digital twin-based production lines, which require real-time processing of massive amounts of data. The 5G network is customized to specific production lines by extending the existing Asset Administration Shell (AAS) usage to incorporate the cumbersome 5G network configuration process.

Lead: Gyeongnam Technopark (IIC Member)

Participants: CTR (Automotive Parts Supplier), Nest Field (AAS Solution Provider), Formation Labs (MOS Solution Provider)

Primary contacts: Gyeongnam Technopark, Chang-seok Lee

| Use Cases Addressed | Benefits | Industries |

|

|

|

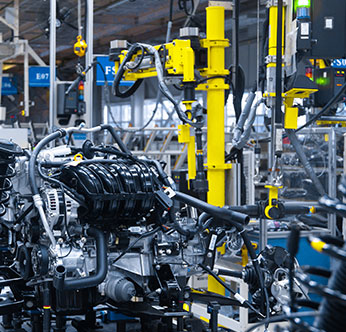

Figure 1. Virtual production lines of AAS digital twin at the CTR Changwon factory.

![]()

Figure 2. The CTR Changwon factory's ball joint assembly line, using digital twins of 5G private network device and production line machines, autonomous mobile robots (AMR), and a vision controller.